History

The start - how it all began

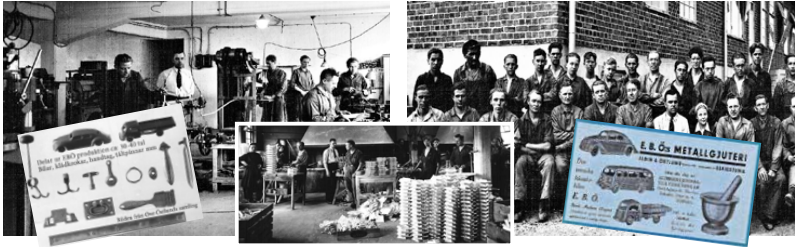

On the last day of the year, December 31, 1921, the company EBÖ Metallgjuteri was registered in Eskilstuna. Behind the company and the three letters in the company name were the manufacturers and brothers-in-law Johan Ruben Eldin, Gunnar Boqvist and Karl Rudolf Gunnar Östlund.

Foundry operations started on the other side of New Year’s Eve in a rented building on Lilla Tvärgatan, in the Östermalm district. Right from the start, aluminum was used to cast simple parts in sand molds, and EBÖ was one of the first metal foundries in Sweden to use fuel oil to heat the melting furnaces.

Eventually, chill casting with cast iron molds became the main method – but initially they relied on more classic sand molds. In the early days of the company, it mainly produced smaller suspension fittings, such as hooks, balcony hangers and various types of knobs. The product portfolio also included urns and pots for flowers.

Our first 100 years

This is the 100-year history of the Eskilstuna-based foundry company, which, through pipes for coffee pots and toy cars, would become a major supplier to the Swedish and international automotive industry during the difficult times of war.

EBÖ metallgjuteri grundas

Verksamheten startar på Lilla Tvärgatan

EBÖ utökar och hyr lokal på Nyforsgatan

EBÖ blir aktiebolag

EBÖ AB bygger egen fastighet i Vilsta

EBÖ AB investerar i maskiner för pressgjutning

Maskinparken för pressgjutning uppgraderas

En maskin för lågtrycksgjutning köps in för tillverkning åt Husqvarna

Ulf Moberg köper EBÖ AB

EBÖ AB förvärvar GGC AB och flyttar till Eskilstuna Norra Hamn

Hans Boqvist, barnbarn till en av grundarna, köper EBÖ AB

Fastigheten i Norra Hamn byggs ut med 1 000 kvadratmeter

Hasselforskoncernen köper EBÖ AB

Hasselforsgruppen tvingas skjuta in extra kapital och EBÖ AB bjuds ut till försäljning

Kurt Andersson köper EBÖ AB och blir tillsammans med Per Larsson huvudägare

EBÖ AB förvärvar ÖW-Bolagen AB och påbörjar flytten till Kungsgatan

EBÖ AB förvärvar BCA AB

Dotterbolaget EBÖ Eesti AS startas i Tartu, Estland

Produktionen består av legotillverkning till 100 procent

Folke Sandvik köper EBÖ AB och blir ny huvudägare

EBÖ AB förvärvar samtliga aktier i bolaget MEPLAKO AB

Namnbyte från EBÖ AB till International Aluminium Casting, IAC

Anläggningen i Hultsfred förvärvas

Anläggningen i Ankarsrum förvärvas

Folke Sandvik säljer IAC till Grönskär Gruppen AB

Anläggningen i Tenhult förvärvas

The advent of die casting

When die-casting machines were purchased by EBÖ from Italy in 1948, the first steps were taken towards what would later drive the company’s success – and also mean the step into the heavy vehicle industry.

In 1948, die casting was a new method that required different types of casting tools compared to die casting, and the tools were also more difficult to manufacture. But the major benefits of die casting were on the material and efficiency side: metal consumption was significantly reduced and the casting process was faster.

During the mid-60s, the demand for die-cast articles increased. EBÖ responded to the market and secured its machinery with two new machines from Germany. By now, ASEA had become a major customer in the die casting segment.

The journey towards vehicle-oriented customers continued in the 1970s. In 1970, EBÖ bought a second-hand low-pressure casting machine in order to supply Husqvarna, AGA and Tunaverken with cylinder heads, lamp housings and rims.

By the end of the 1990s, the die casting segment had increasingly displaced gravity die casting. Customers such as Volvo and Scania drove demand for die-cast items to record levels.

At the time of writing, as EBÖ has become IAC and celebrates its 100th anniversary, all remaining die casting has been transferred to the Tartu site in Estonia. The Swedish plants in Gredby, Hultsfred, Ankarsrum and Tenhult are dedicated exclusively to die casting – with the majority of production going to automotive giants Volvo, Scania, MAN and Daimler.